Dynamite does indeed come in small packages, and our new B-series Skid Steer Loaders are living proof of this. With a comprehensive range and high flow hydraulic package options, our Skid Steer Loaders are the ultimate tools in versatility.

Our Skid Steer Loaders are customer-focused and designed and built to deliver optimal performance, reliability, and efficiency. They are the perfect solution for all your needs. With a full range of features and options, our Skid Steer Loaders are versatile, reliable, and efficient, making them the go-to choose for any job site.

Join the ranks of satisfied customers who have come to rely on our machines to tackle and solve their construction challenges for more than 50 years.

Comprehensive planned maintenance solutions designed to enhance uptime, extend equipment life, and ensure peak performance on every job.

Advanced protection plans offering extensive coverage to safeguard your equipment, reduce downtime, and ensure peace of mind.

A powerful telematics system providing real-time insights into equipment performance, efficiency, and location to maximize productivity.

Seamless remote diagnostics and support tools enable quick issue resolution, minimize delays, and keep your machines operational.

It’s both thrilling and inspiring to visit our clients’ sites, where one is able to see first-hand what CASE Construction Equipment has helped develop and bring to life. We eagerly anticipate the many exciting projects Northlands Holdings has in the works, as the team makes ambitious strides toward developing residential, retail, and business estates that positively impact the community.

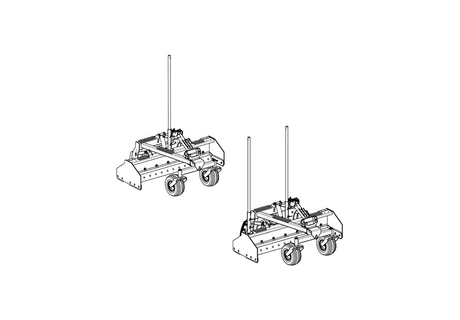

DRIVE MOTOR PUMP CONTROLS

The improved hydrostatic pump controller on EH machines allows the operator to maintain a straighter path without having to make adjustments.

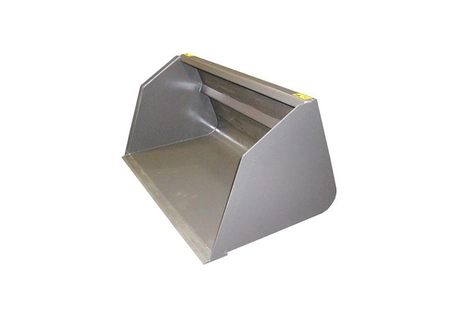

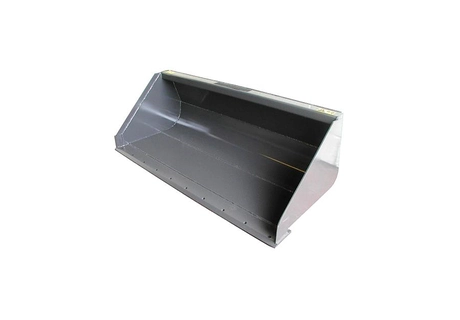

OPTIMAL PUSHING POWER

The cylinder geometry optimizes the skid steer’s push and pull power, while the bucket support bearing directly on the chassis further adds to its pushing power.

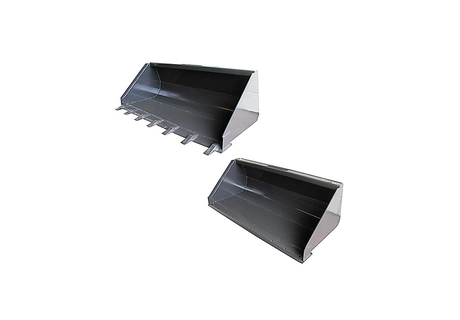

HIGH VERSATILITY

The hydraulic system delivers fast cycle times. The Connect Under Pressure (CUP) system allows the operator to plug hydraulic tool hoses with no wrenches.

RADIAL AND VERTICAL BOOM

CASE has revised its skid steers line up to boost performance and productivity for an ever wider range of customers. The revised CASE skid steers range includes radial lift skid steers (SR models) and vertical lift skid steers (SV models).

SAFE AND EASY MAINTENANCE

Convenient cab tilting. With just two retaining bolts, the cab is easy to tilt, providing access to hydraulic and transmission components when necessary. A safety locking system that prevents the cab from dropping is automatically activated. Best-in-class serviceability. Easy access, daily service points grouped together and remote-mounted filters mean it’s easy to keep all CASE skid steers working to their maximum efficiency.

The wide door, the grab handles and the lower threshold provide easy access to the cab. All the closed cab models have suspension seats and optional air suspension heated seats for the ultimate in comfort. The cab is completely sealed to reduce the amount of noise and dust thanks to the full cab glazing and door. Our cab – the widest in the industry – provides plenty of room for comfortable operation, with greater headroom and legroom, more space between the control levers and easy access to the seat

The wide door, the grab handles and the lower threshold provide easy access to the cab. All the closed cab models have suspension seats and optional air suspension heated seats for the ultimate in comfort. The cab is completely sealed to reduce the amount of noise and dust thanks to the full cab glazing and door. Our cab – the widest in the industry – provides plenty of room for comfortable operation, with greater headroom and legroom, more space between the control levers and easy access to the seat

Narrower palm grip for better ergonomics

Closer switch layout and smaller head size for easier operation

Smaller EH pods with more legroom for the operator’ comfort