Since the inception of our backhoe loader in 1957, CASE has been setting the benchmark for performance, versatility, and utilization with in the industry. We have always pushed the boundaries and lead the way with world-first innovations that focus on solving customer problems and improving production and reliability.

Our new V-series Backhoe Loaders continue to build on this legacy of excellence, redefining operator comfort and performance with a brand-new cab structure and interior.

We understand that quality and performance are non-negotiables, which is why all our Backhoe Loaders are fitted with our FPT engines that deliver class-leading power, torque, and fuel efficiency. Our Backhoe Loaders are packed with class-leading features, making them the most sought-after machines for any jobsite.

As a construction equipment owner, you can count on CASE, Backhoe Loaders to deliver the performance and reliability to get the job done right.

Choose CASE Backhoe Loaders and join the ranks of satisfied customers who have come to rely on our machines to tackle any challenge.

Comprehensive planned maintenance solutions designed to enhance uptime, extend equipment life, and ensure peak performance on every job.

Advanced protection plans offering extensive coverage to safeguard your equipment, reduce downtime, and ensure peace of mind.

A powerful telematics system providing real-time insights into equipment performance, efficiency, and location to maximize productivity.

Seamless remote diagnostics and support tools enable quick issue resolution, minimize delays, and keep your machines operational.

WALKAROUND

FEATURES

BENEFITS

FEATURES

BENEFITS

FPT Multijet Engine

The FPT engine delivers a big performance in a small package with the lowest maintenance cost in the market:

FPT: a leader in engine technologies.

One side engine serviceability

Always available, never defined

The CASE 695SV allows the operator to select 3 different steering modes: 2-wheel steering – road steer for standard operations and 4-wheel steering for agile and fast operations, and crab steer for restricted areas. This ensures great versatility and outstanding maneuverability. It’s easy and safe to change the steering mode. The CASE 695SV is equipped with 4 equal size wheels to guarantee better weight distribution and more traction.

The King’s DNA

Modulated power

The load sensing hydraulics provide just the right amount of oil for each task, even when the engine is running at low rpm. This results in fuel savings of up to 14% compared to traditional gear pumps. CASE is the only Backhoe loader manufacturer offering closed hydraulic centre whatever the choice of pump. Closed hydraulics enable simultaneous movements independent from work load and functions delivering constant power, better operator controllability and fast cycles.

No Stress power

Safe productivity

The job has never been so easy!

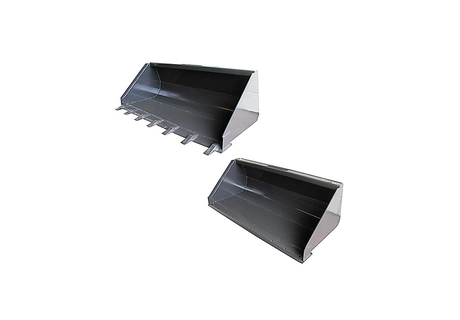

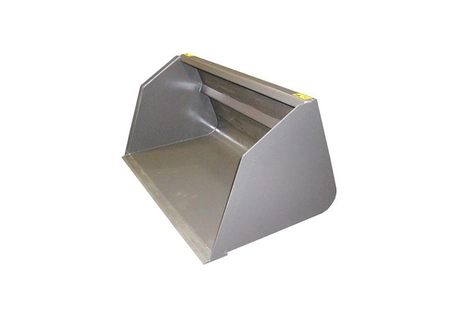

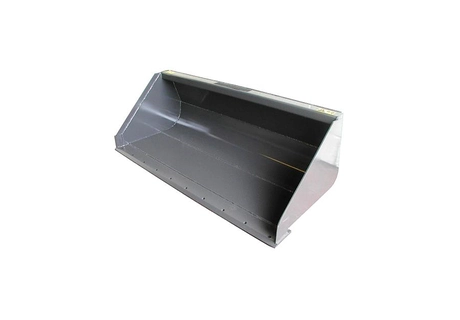

Curved front loader arms improve truck loading while mechanical self-levelling assists the operator. The return-to-dig function significantly reduces operator effort on repetitive loading operations and speeds up the whole cycle. Excellent front loader visibility and the mechanical self-levelling feature make loading and unloading pallets really quick and simple.